What method?

Choosing the right method

It is important that we use the right method for the contaminant we are interested in. Failure to do so can mean that the results we obtain are meaningless.

Ideally we should use a properly validated method. Such methods are available from bodies such as:

- The United Kingdom Health and Safety Executive (the MDHS series)

- The US National Institute of Occupational Safety and Health (NIOSH)

- The US Occupational Health and Safety Administration (OSHA)

- In-house company methods.

The NIOSH and OSHA methods can be viewed and downloaded from the following web sites:

A summary of sampling and analytical methods can be found on the websites of manufacturers of air sampling equipment, including the following:

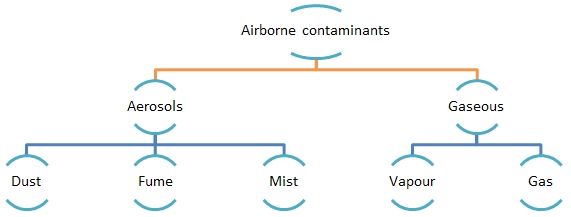

Types of contaminant

One of the main factors influencing the sampling method is the physical form of the contaminant. Airborne contaminants can be classified as either:

- Aerosols, or

- Gases/vapours

Aerosols are solid or liquid particles that are suspended in the air.

- If the particles are solid, they can be classed as either dust or fume.

- Liquid particles are a mist.

Gaseous contaminants are normally classified as:

- A gas: always gaseous at room temperature

- A vapour: a gas that has evaporated from a liquid.

With aerosols the contaminant is normally captured on a filter, which will trap most particles. However, with gases, different methods are needed for different contaminants.

Sampling for aerosols

The particulates of significance to occupational hygienists are all liquid or solid particles which may be inhaled.

Personal sampling for dusts, fumes and mists is normally carried out using a pump to draw air through a filter which is contained in a holder usually referred to as a "sampling head". The pump is fixed to the worker's belt with the sampling head normally attached to the collar or lapel.

Various "sampling heads" used for dust sampling

Image source: http://airsamplingsolutions.com/

A filter cassette - the standard sampling head used for total inhalable dust in the USA

Image source: http://www.zefon.com/

What do you want to capture?

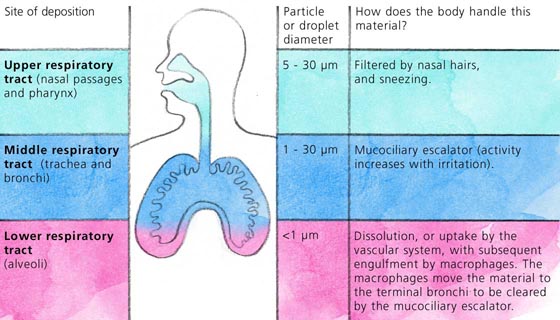

The type of sampling head used, together with the flow rate, will determine the size range of the particles captured.

So firstly, we need to decide whether we want to capture:

- The inspirable dust, which is all the airborne particles which can enter the nose and mouth (also called the total inhalable dust)

- The respirable dust, which is only those particles which can reach the deepest regions of the lungs.

Only particles less than 10 microns in diameter can reach the deep lung, so when sampling for respirable dust, we have to use a device which prevents the larger particles from reaching the filter.

It is actually quite rare that we want to sample for the respirable fraction. We normally only do this for dusts which affect the lung but do not cause harmful effects to other parts of the body. Very few dusts do this, so in most cases you will want to sample for total inhalable dust.

If you are unsure, how can you find out whether you need to sample for respirable dust?

Luckily the exposure limit for the substance will tell you if you need to sample for respirable dust. Unless it specifically mentions that the limit is for respirable particles, you should carry out sampling using a method for total inhalable dust.

Sampling for gases and vapours

The method will depend on the contaminant of interest.

A common method used when taking personal samples for organic compounds is to draw air through a glass tube packed with activated charcoal, silica gel or a porous polymer.

Image source: http://airsamplingsolutions.com/

Diffusive tubes and badges can also be obtained which use the same collecting medium but do not require a pump. After sample collection in the workplace, the badge is analysed in the laboratory, usually by gas chromatography (GC).

Image source: http://airsamplingsolutions.com/

One problem with collecting contaminants on tubes or badges is that it will normally take several days before the sample results are available, so these are not suitable when we need a quick answer (for example, in an emergency situation).

Direct reading instruments

Direct reading instruments are useful for quick results for gases, vapours, mists and dusts, especially in emergency (spill) situations.

They are also useful as a screening tool to demonstrate that exposure concentrations are:

- Sufficiently low (so no further sampling is needed)

- Above the OEL and further controls are needed (no further sampling)

- Close enough to the OEL that further sampling is required.

They can also help to identify which work tasks contribute most exposure in a given shift.

In most cases these instruments can only be used to take static samples.

Colorimetric indicator tubes

Colorimetric indicator tubes are available for a wide range of many gases and vapours.

The tubes contain material that has been treated with chemicals, which react with the contaminant of interest to produce a colour change. With most types, the length of the colour stain is proportional to the concentration of the contaminant in air.

Image source: http://www.sensidyne.com/

Colorimetric indicating tubes are NOT suitable for assessing airborne dusts.

Example scenarios

Scenario 1

Here we can see a powder being discharged from a blender into an open topped drum. A limit of 1mg/m3 has been assigned to the dust.

What type of sampling equipment would you use here?

Image courtesy of author

The contaminant is a dust but unless the limit specifically mentions that it applies to respirable dust, you should sample for the total inhalable fraction.

Scenario 2

Here we can see a worker carrying out arc welding. The main contaminants given off are metal fume and ozone.

Image courtesy of author

What sampling method would you use for the welding fume?

You would use a sampler for total inhalable dust. Welding fume is an aerosol – it consists of fine particles of metal oxide suspended in the air.

What sampling method would you use for the ozone?

A colorimetric indicator tube would probably be the best method to use here.

Scenario 3

This worker is about to add a solvent (dichloromethane) to a mixing vessel. He performs this task several times over the course of the shift.

Image courtesy of author

What sampling method would you use to measure his personal exposure to the dichloromethane over the shift?

An absorption tube and pump would be the best method to use here.

What sampling method would you use to measure his exposure to the dichloromethane during one short operation?

Colorimetric tubes are available which could be used to take a "grab" sample which would give us an estimate of his exposure during the task – provided that we took the sample from his "breathing zone".