Do I need to sample?

Introduction

There are lots of different reasons why you might want to carry out air sampling. They might include:

- To assess the risk of a particular task/substance

- To routinely monitor exposure

- As a result of concern expressed by workers

- As a result of concern expressed by management

- "Abnormal" medical results from health surveillance

- To evaluate if controls are working properly

- After a change in the manufacturing process

- It is a regulatory requirement

- To know if it is safe for re-occupancy after a spill or release

- To gather baseline exposure data for legal documentation.

You might be able to think of other reasons.

What should be considered prior to performing a survey?

Image courtesy of author

You need to consider:

- Whether an analytical method is available

- The cost of analysis

- The level of sampling and analytical accuracy necessary

- Is there an occupational exposure limit (OEL)?

The first question you need to ask before you start is whether air sampling is really necessary!

We can make this decision during an initial assessment of the processes where the substances are being used. Often, sampling is only really necessary for routine monitoring, or where you need more information about exposure.

Don't sample...

- When exposure is clearly LOW - if it is obvious that there is little chance of exposure occurring, or that exposures will be very low, there is usually little point in using valuable time and resources by carrying out sampling on the process.

- When exposure is clearly HIGH - if your observations suggest that the contaminant is not being controlled properly, it is normally sensible to decide on what control measures are needed and implement them, rather than waste time by carrying out sampling to prove what you already know. In these cases sampling should only be carried out either to find out what degree of control is needed or check that controls are adequate once they are in place.

Carrying out an initial assessment

Before you decide whether to carry out sampling you should carry out an initial assessment of the processes of concern. The objective of the initial assessment is to:

- Determine how and when workers can be exposed to hazardous agents

- Make a judgement about the degree of exposure.

The questions you are trying to answer typically include:

How toxic are the substances?

The toxicity of a substance has a significant bearing on the risk. Many substances have very low OELs and it is unlikely that airborne concentrations at the OEL would be visible.

What quantities of the substances are being used?

There is usually a greater risk of exposure where relatively large quantities are handled. If only a few grams are used, then the risk will usually be low. However, you need to bear in mind its toxicity.

How often and how long are they used for during a shift?

A substance which is used regularly for long periods of time during a shift is more likely to lead to significant exposures to contaminants.

What controls are being used and do they appear effective?

If appropriate control measures are in place, there is less chance that significant exposure will occur. However, make sure that the controls are in a good state of repair and are properly used by the workers.

Are there any obvious signs of dust around the process or other evidence of contaminants escaping?

These are usually good evidence that workers can be exposed to the substances. Try to work out where the dust is coming from.

How many people can be exposed to the substance?

This has a number of implications for both sampling strategy and control of exposure. As we will see later on, the number of samples we take will depend on the numbers exposed. If we decide exposure is not satisfactorily controlled then we are more likely to install other types of controls if a large number of people can be affected.

Example scenarios

During an occupational hygiene initial assessment, the assessor would most likely select locations where samples should be taken subsequently.

Example 1

You are assessing a warehouse in a pharmaceutical production plant. All the chemicals used for the manufacture of the product are stored here.They are kept in closed containers and NO dispensing of the products takes place in the warehouse. They are delivered to the process as required by forklift truck.

From the information provided, would you think air sampling is necessary?

Image courtesy of author

There is little point in carrying out sampling here. It seems unlikely that there will normally be any contaminants present in the workplace atmosphere. However, we might need to re-consider if any dispensing took place, or in the event of a major spillage.

Example 2

Here we can see two workers handling trays of wet granulated powder, which is a mixture of different materials, including an active pharmaceutical ingredient.

From the information provided, would you think air sampling is necessary?

Image courtesy of author

Whenever you are not confident, it is probably a good idea to sample. It is probably worthwhile carrying out sampling here, particularly if we want to assess exposure to the active pharmaceutical ingredient. There is evidence of dust on the floor, which suggests controls need to be improved, but we can't be certain about the workers' exposures to the hazardous components of the mixture.Example 3

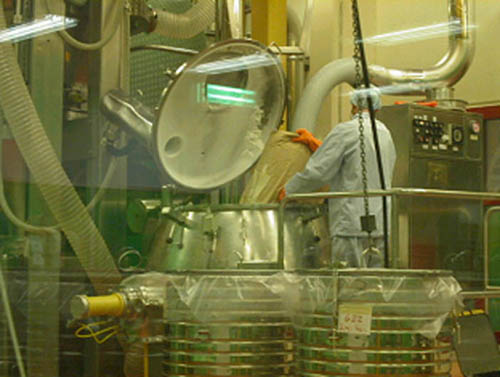

Here we can see a process where a worker is loading various materials into a mixer where they will be blended together. Some of the materials are toxic while others are relatively harmless.

From the information provided, would you think air sampling is necessary?

Image courtesy of author

It is probably worthwhile carrying out sampling here. Observations alone are unlikely to tell us whether exposure to the substances, particularly the more toxic ones, is acceptable.Example 4

Here we can see a Quality Control Laboratory. Samples of products (a few grams) are brought here for analysis.

From the information provided, would you think air sampling is necessary?

Image courtesy of author

There is little point in carrying out sampling here. Only small quantities of substances are handled and – particularly if the more hazardous ones are handled in the fume cupboard exposure – should be minimal. However, we still need to review the toxicity of the substances to ensure none are carcinogenic or extremely toxic.Example 5

Here we can see a worker cleaning out equipment that is used in pharmaceutical manufacture. Some of the chemicals used in the production process are quite toxic and have low exposure limits.

From the information provided, would you think air sampling is necessary?

Images courtesy of author

If we look closely at the second picture we can see dust deposits on the floor. This certainly suggests that we need to improve control. Worker exposure during this job will depend on how dirty the equipment is, but this type of operation often leads to high exposures. Air sampling may be needed to help us confirm this, but if our observations suggest there are obvious problems it might be better to move straight on to deciding what we are going to do about them.